FIXING OF FOUNDRY DEFECTS BY LASER WELDING

Welding machine has wavelength of 1064 nm and energy of 100 J which helps us to fix mechanical damages and foundry defects of metal casts. Part of the rework is also effacement of weld to the requested shape.

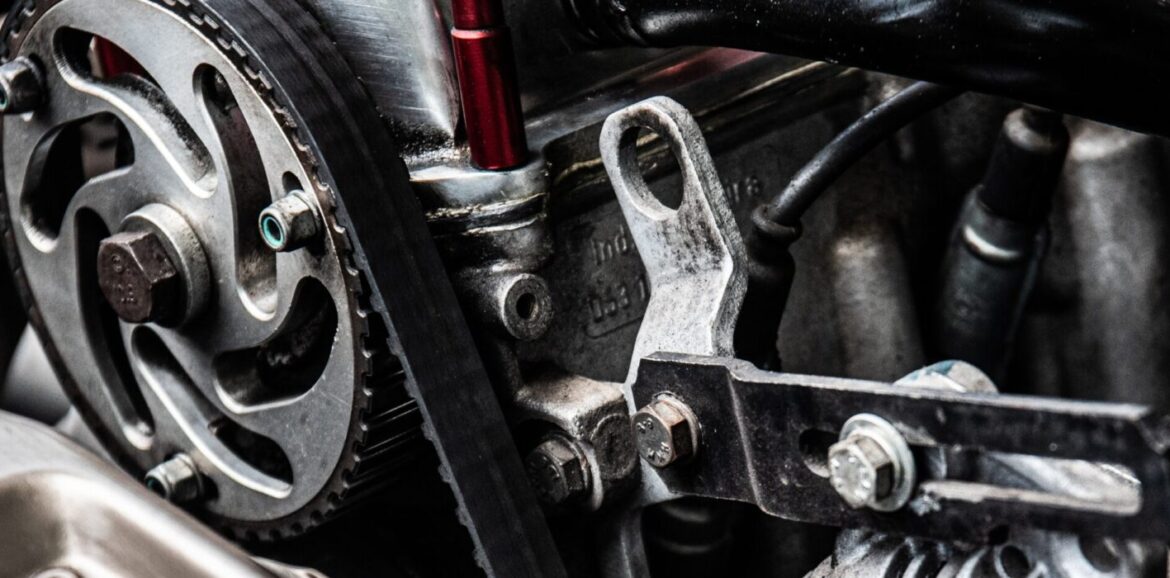

WELDING OF WORN-OUT PARTS

When we have worn-out metal parts, laser helps us to weld worn out layer or protecting layer. By this way we can weld for example worn out cutter, shaft under bearing, damaged molds for castings, or weld the layer resistant to mechanical worn out.

WELDING OF THIN METAL COMPONENTS

Welding of thin components by laser is more effective and more precise. The zone affected by heat is minimal and therefore also damages made by heat are almost none.

WELDING OF PARTS FROM VARIOUS MATERIALS

Welding by laser allows us to join different metal materials, e.g. aluminum with copper with help of special welding wire, or hard metal with steel with help of brass.